Team Bath Racing

The Situation

Building on an existing relationship

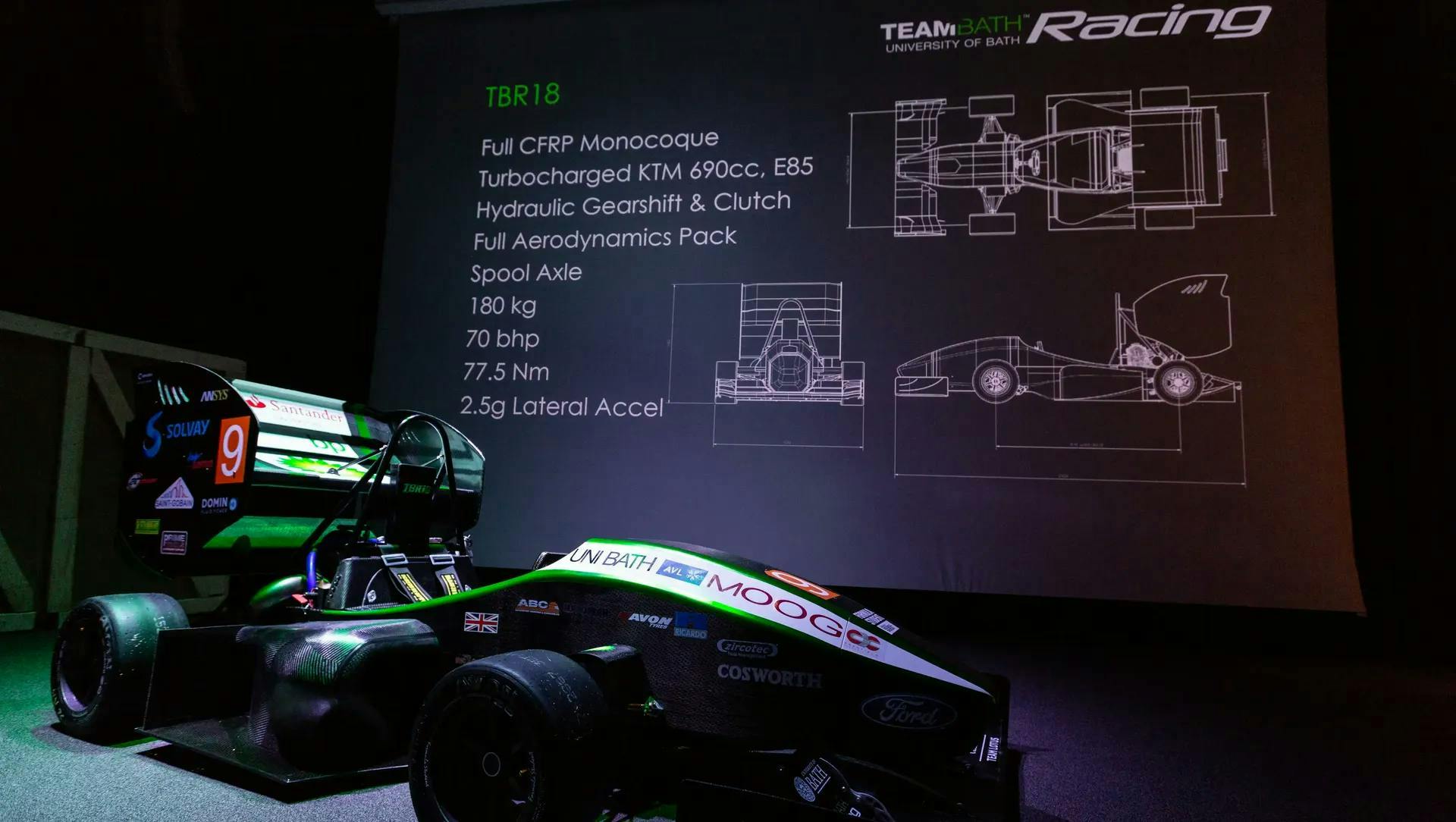

Every year, a team of engineering students from the University of Bath competes in the Formula Student motorsport competition. The competition challenges student engineers to design, build and race a single-seat car over a two year period. Known as Team Bath Racing, the University of Bath students are the most decorated British team in the entire competition.

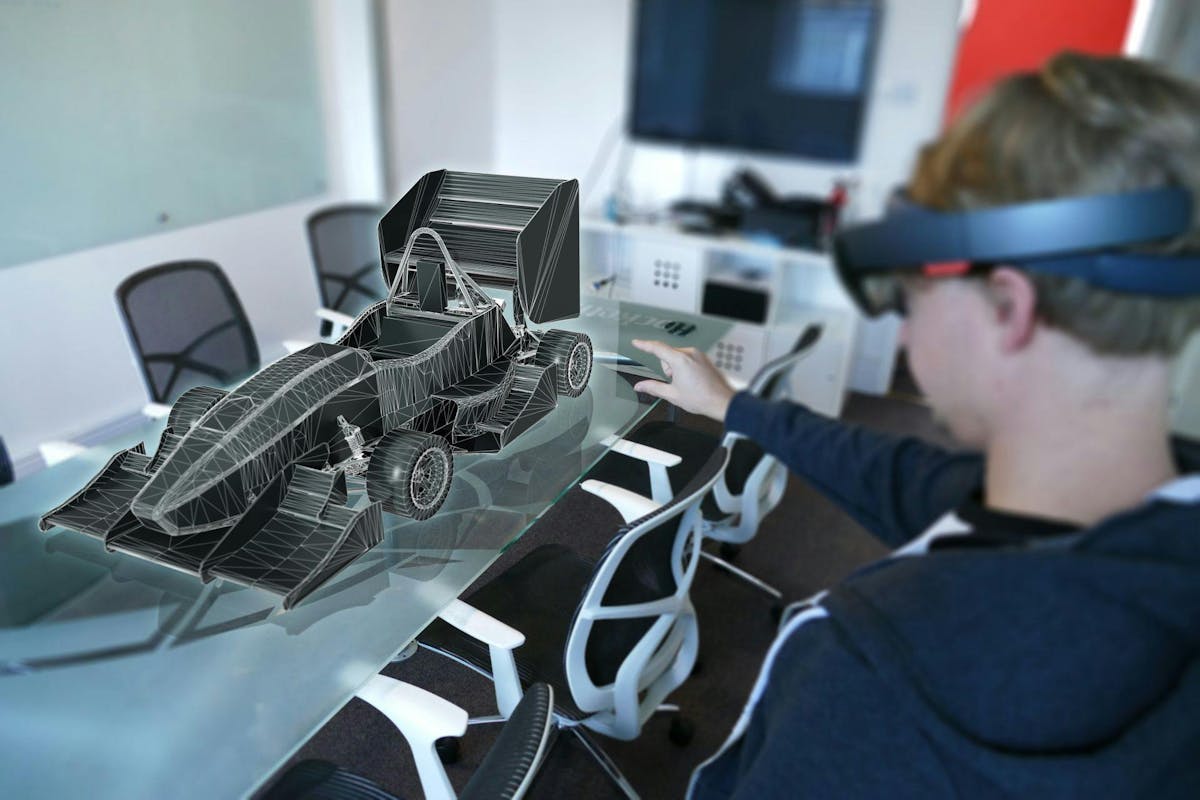

As a community outreach project, Rocketmakers designed an augmented reality (AR) model for TBR’s 2017 car. The model was displayed on the Microsoft Hololens headset, and used as part of the students’ presentation to judges. This presentation was an important part of the overall competition, although not nearly as exciting as watching the car’s time trials at Silverstone.

In the Autumn of 2018, Rocketmakers and Team Bath Racing decided to collaborate again, but this time to raise the stakes. The goal would be to create an AR-powered tool which would be used in the construction of the 2019-model car.

The Task

Conceiving the world’s first AR automotive construction tool for competitive race car construction

Both teams wanted to create and test a tool which was genuinely useful, could operate easily within the constraints of current AR headset technology, and required minimal advance work by the students. Various ideas for how to deploy AR technology were considered, including an option which would allow the students to plan the placement of the engine, brakes, and drive train in 3D.

Our Discovery

Advancing state of the art construction for bespoke, high performance cars

After multiple discussions between the Rocketmakers design team and TBR’s department heads, it was decided to create a tool for applying carbon fibre laminates to the car’s monocoque chassis. As one misplaced carbon fibre segment can have enormous negative consequences for the integrity of a car part, any improvement to the carbon fibre application process provides significant benefits.

Carbon fibre laminates are typically applied by robots in production vehicles, but for bespoke car production it is always applied by hand. This application process is one of the most physically and mentally demanding parts of the construction process.

Current state-of-the-art, even for Formula 1 car construction, consists of placing a computer screen nearby and “eyeballing it.” One misplaced carbon fibre segment can have large negative consequences for the integrity of the final result. The process is extremely time consuming, and the TBR engineers work in shifts over an exhausting 36 hour period.

The goal was to create an AR tool which would generate an augmented reality version of the car monocoque which could be “placed” on top of the real monocoque. The AR display would then show the headset wearer the correct shape, location, and orientation for each carbon fibre segment in the correct order for each segment.

The Solution

Working within current state of the art technology

Once conceived, the idea for the new tool required extensive experimentation to get right. To work effectively, the Rocketmakers team would need to push the limits of Microsoft’s Hololens headset to its absolute limits.

Although the Hololens was the most powerful commercially-available headsets at the time, the complexity of virtual images they could display was still limited. Team Bath Racing had a set of 3D CAD files for every part of the car, but these included too much data for the Hololens to process. The Rocketmakers design team had to develop a system for converting the CAD files into something the Hololens could process while still retaining enough information to ensure the AR tool was useful.

Once the Hololens could process the images, the Rocketmakers team added data displays to show the correct shape, location, and orientation for each carbon fibre laminate. This allowed the wearer to clearly see exactly where and how to apply the laminate as he looked at the car body, with no need to look away to a computer screen.

The Result

A world-first for competitive race-car design

With a Microsoft Hololens in hand, the Rocketmakers team travelled to the Team Bath Racing workshop on the University of Bath campus in May 2019. After some initial testing, the new tool was used to lay the first carbon fibre laminate laminates, and history was made!

Although augmented reality had previously been used in demonstrations by car manufacturers, this is believed to be the first time the technology will have been used to build a car intended for use in competitive racing.

The Impact

Global press coverage

The news of the world’s first AR-assisted manufacturing of a competitive racing car made headlines across the UK in publications as diverse as RaceTech magazine and ITV News.

Rocketmakers was contacted soon after the story appeared by engineers from the Renault Formula 1 team, who requested a demonstration of the new technology in person.

Thanks to its work with Team Bath Racing, Rocketmakers was also selected as the winner of the Most Exemplary use of Virtual or Mixed Reality category at the 2019 Sparkies Awards, run by TechSPARK.

Rocketmakers incorporated our 3D model into a mixed reality platform so that our visualisation capabilities have exceeded anything that we've done before.

Rocketmakets introduced us to the Microsoft Hololens which allows us to bring interactive animations and holograms into a real world environment. It's going to be invaluable to all our designs.

We took this 3D model and developed it into an augmented reality space, where a Microsoft Hololens user could then interact with the car. Using the Hololens, users can select different race car components to analyse aerodynamics, crash impact, manufacturing materials, and structural connections.